Gas Process

Gas Process

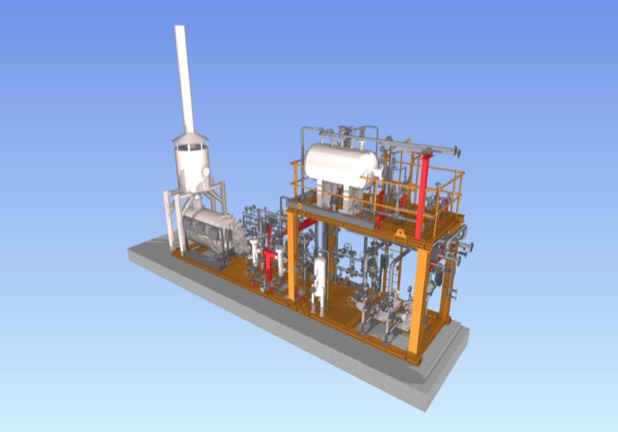

Processing Solutions for Natural Gas, Associated Gas & Refinery Fuel Gas

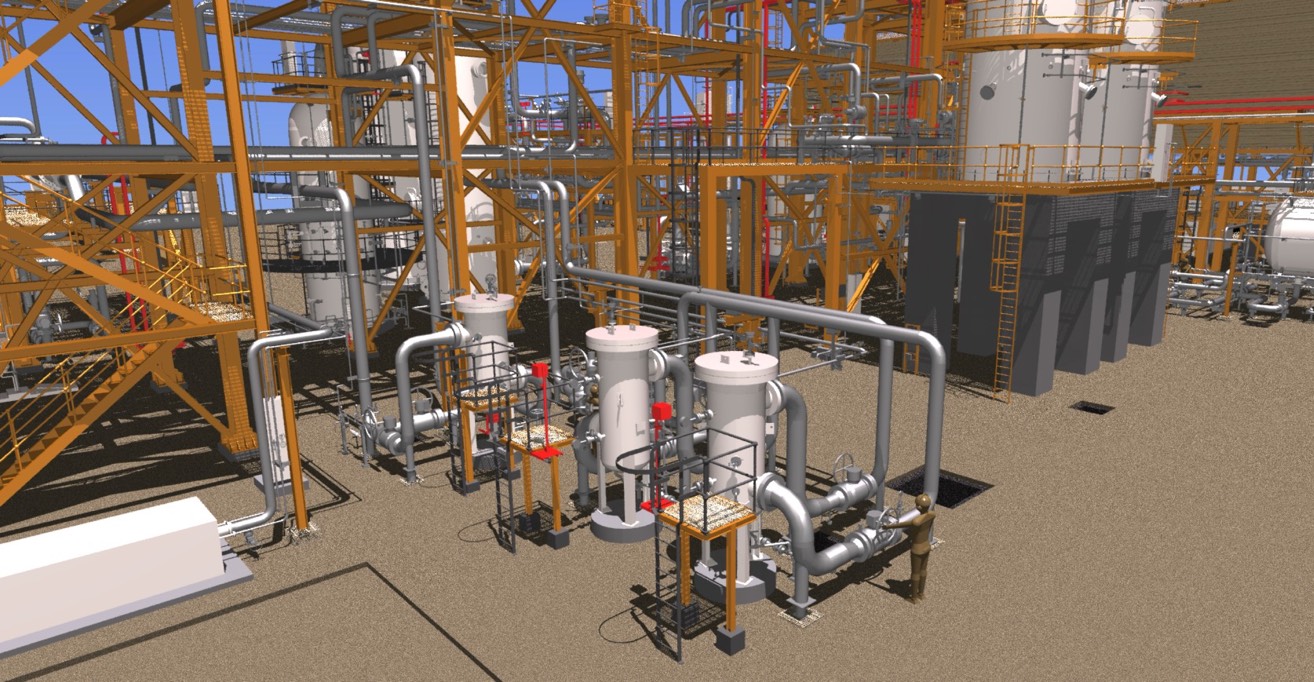

We offer a variety of customized solutions for gas processing, treating and conditioning.

- Gas Sweetening to meet H2S/Mercaptan/CO2 specifications through:

- Chemical Absorption (Primary, Secondary & Tertiary Amines)

- Physical Absorption (NMP)

- Molecular Sieve Adsorption

- Gas Dehydration to meet water specifications through:

- Low Temperature Separation Unit (w/Glycol Injection & Regeneration)

- TEG Dehydration

- Adsorption (using Silica Gel, Mole Sieves & Activated Alumina)

- Hydrocarbon Dew Point Control for heavy hydrocarbon removal from Fuel Gas

- Mechanical Refrigeration

- Joule-Thompson Method

- Adsorption (using Silica Gel)

- Scalable design for plants processing 5 to 200 MMSCFD. Additional capacity achievable through multiple trains.

- Optimized design delivered based on gas specification requirements.

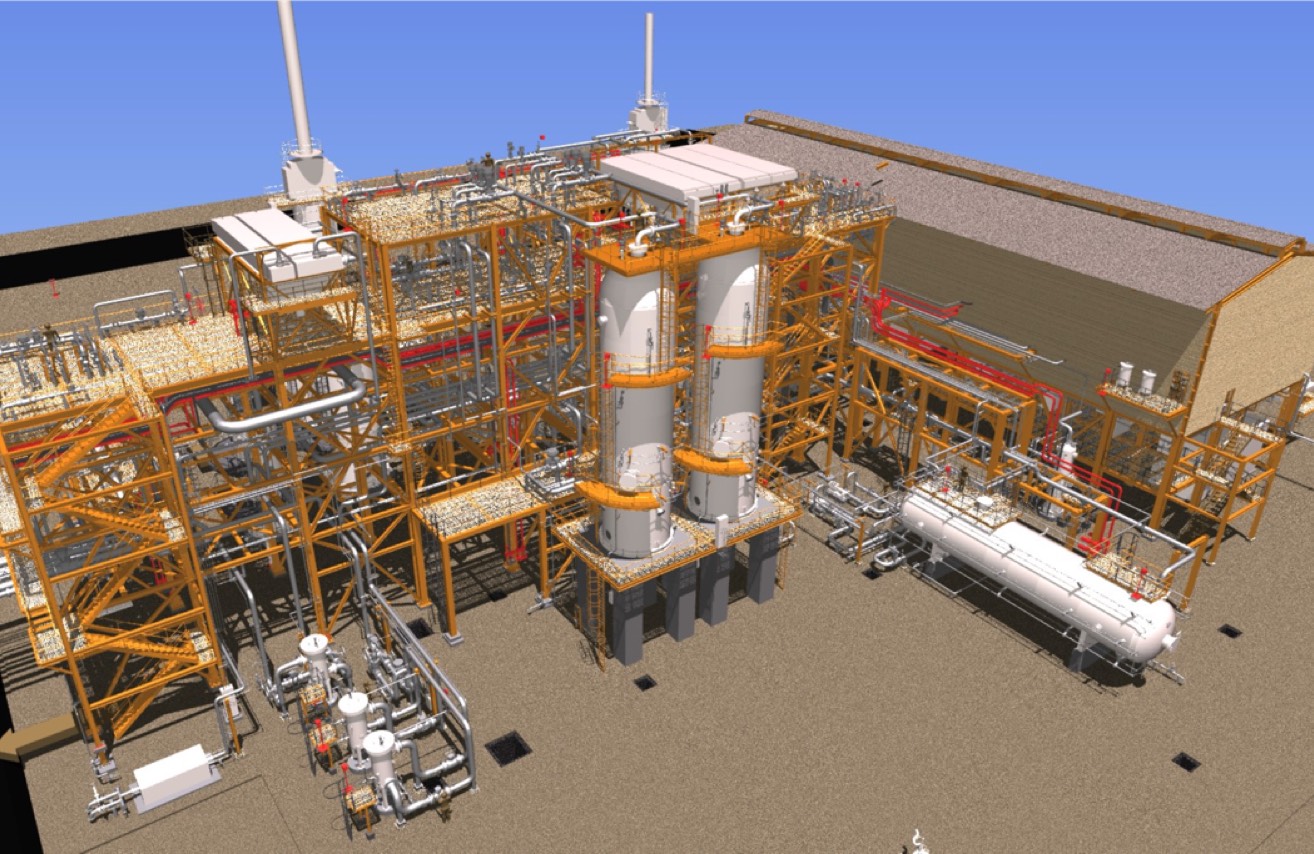

In addition, we offer engineering solutions for gas fractionation.

- Ethane Recovery from Sweet Gas

- Turbo expander & Mechanical Refrigeration

- LPG Recovery from Sweet Gas

- Mechanical Refrigeration

- Joule Thompson Method

- Saturated Gas Plant Design for Refinery Off-Gas

- NGL Fractionation/Saturated Gas units to produce commercial grade:

- Ethane

- Propane

- Butane

- Pentane plus

- Condensate Stabilizer Package

- Scalable design for plants processing 5 to 200 MMSCFD. Additional capacity achievable through multiple trains.

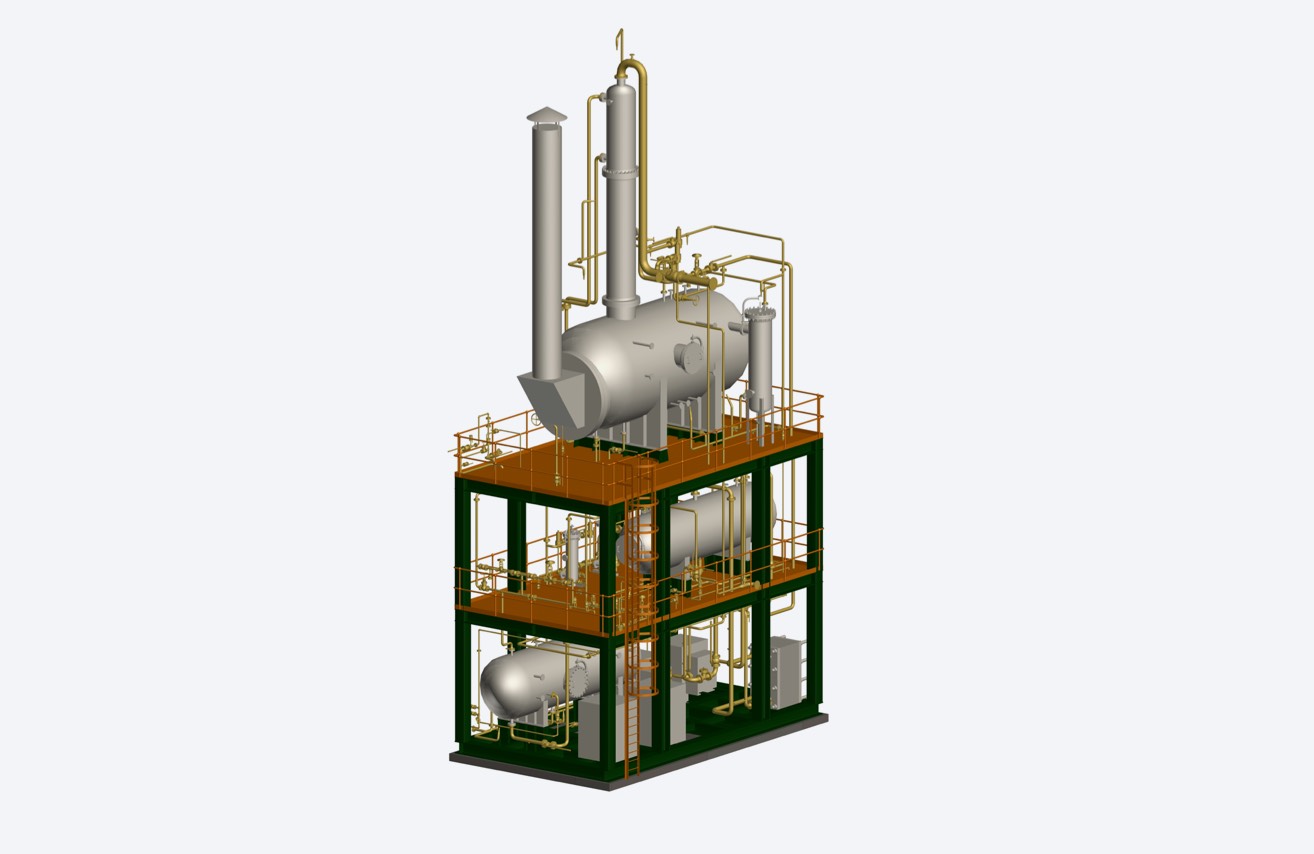

Sulfur Recovery Unit

Partnering with reputable technology licensors, Petro-Techna also offers solutions around Sulfur Recovery Units. We specialize in technical evaluation and selection of the licensor based on project requirements and integrated plant delivery based on the technology selected.

Find Out More

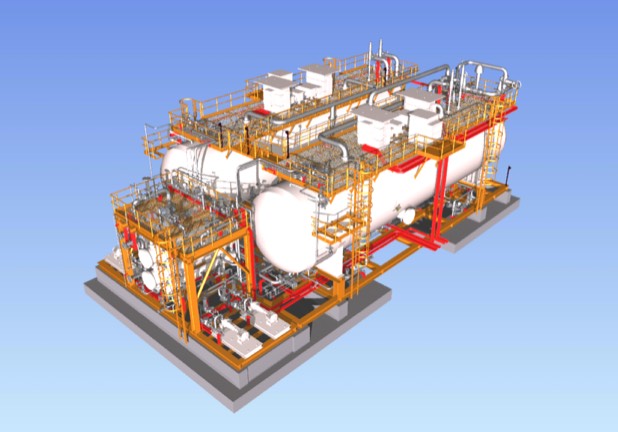

Liquid Process

With over a hundred operational installed units world-wide during the past 3 decades, Petro-Techna represents a premier trusted and well-known brand in the oil desalting field.

Water Process

We offer comprehensive produced water treatment solutions to meet the entire range of wastewater treatment requirements. Our solutions are compact, fit-for-purpose, and engineering to meet even the stringent disposal criterion.

Utilities / Auxiliaries

Petro-Techna provides custom design closed loop heat transfer systems utilizing various media including commercial hot oils, water/glycol mixtures and other fluids.