We offer customized grid solutions based on AC as well as AC/DC technologies. These can be coupled with Petro-Techna proprietary Multimode Ampere System (MAS):

- To control and optimize the electrostatic field

- Break up the rag layer at the interface

We offer a diverse range of solutions and products for separation, treatment and stabilization of oil.

With over a hundred operational installed units world-wide over the past 3 decades, Petro-Techna represents a premier, trusted and well-known brand in the oil desalting field. Our units operate in:

We offer customized grid solutions based on AC as well as AC/DC technologies. These can be coupled with Petro-Techna proprietary Multimode Ampere System (MAS):

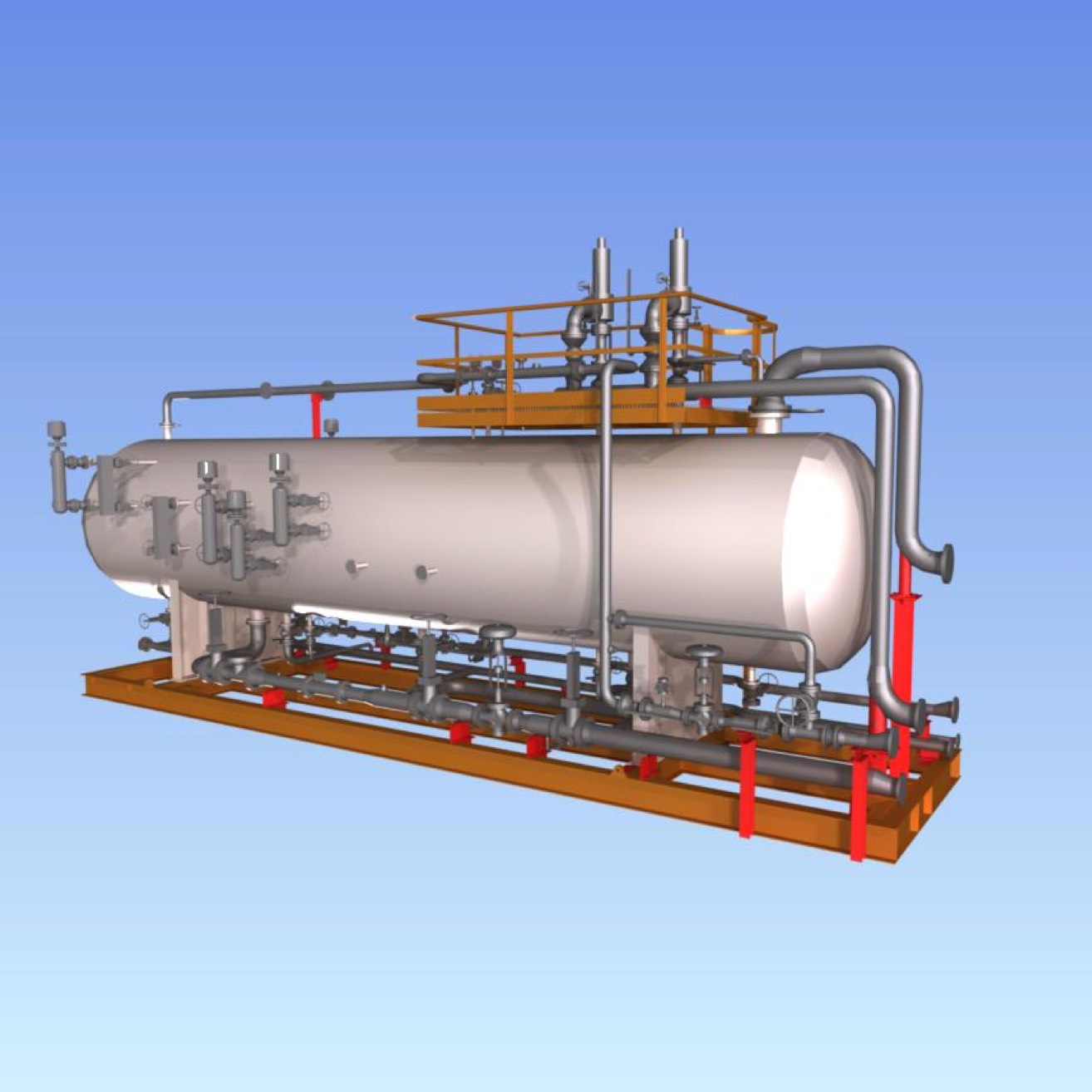

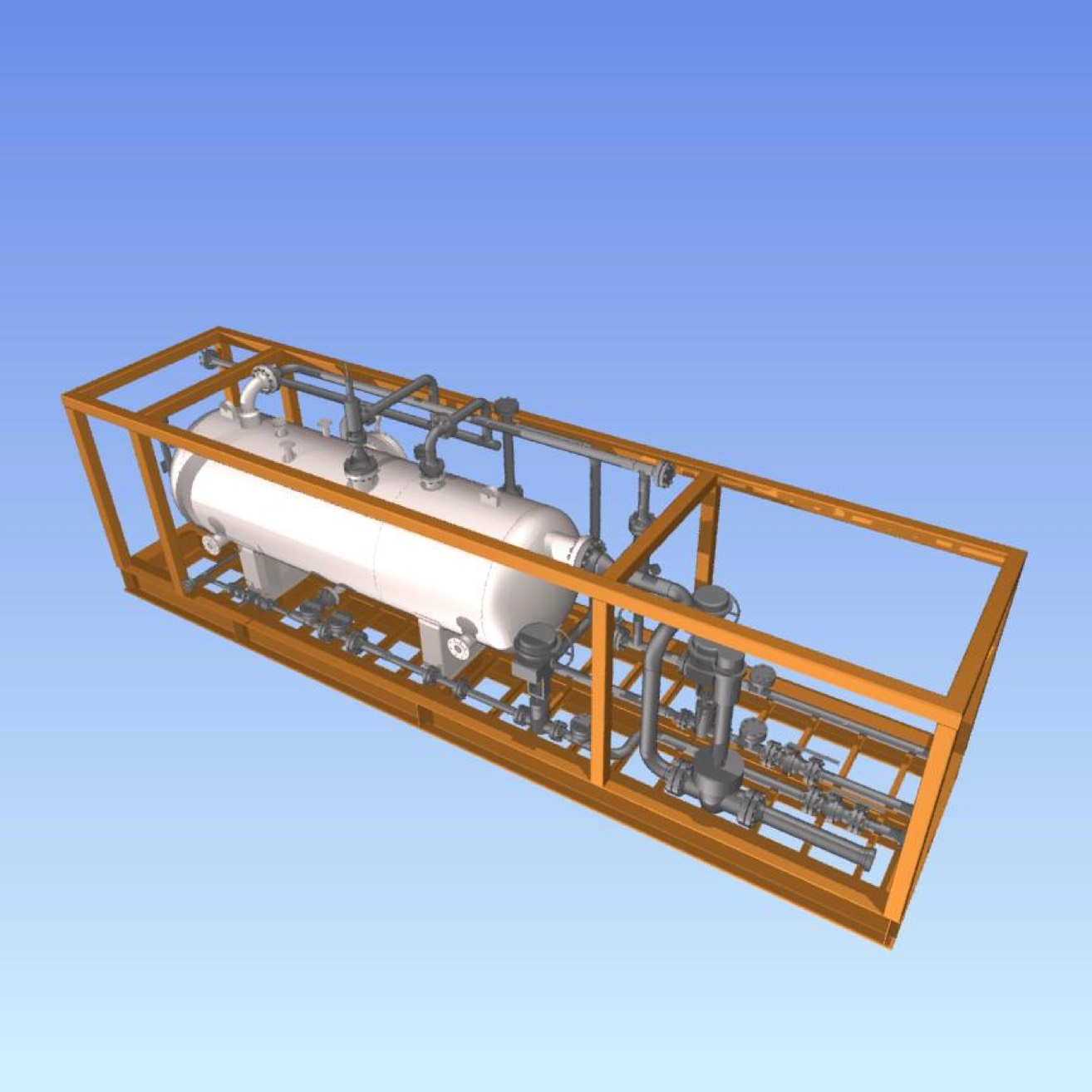

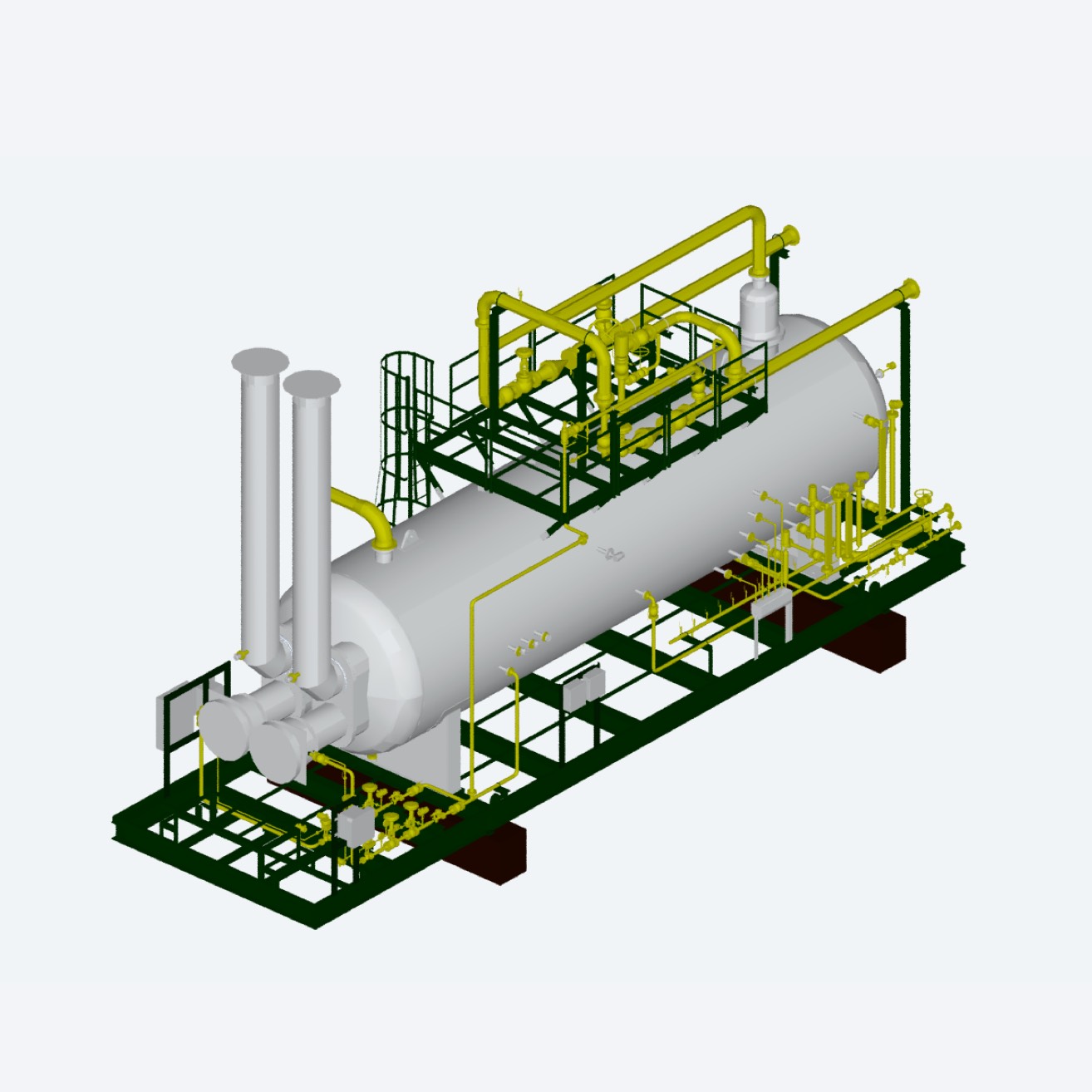

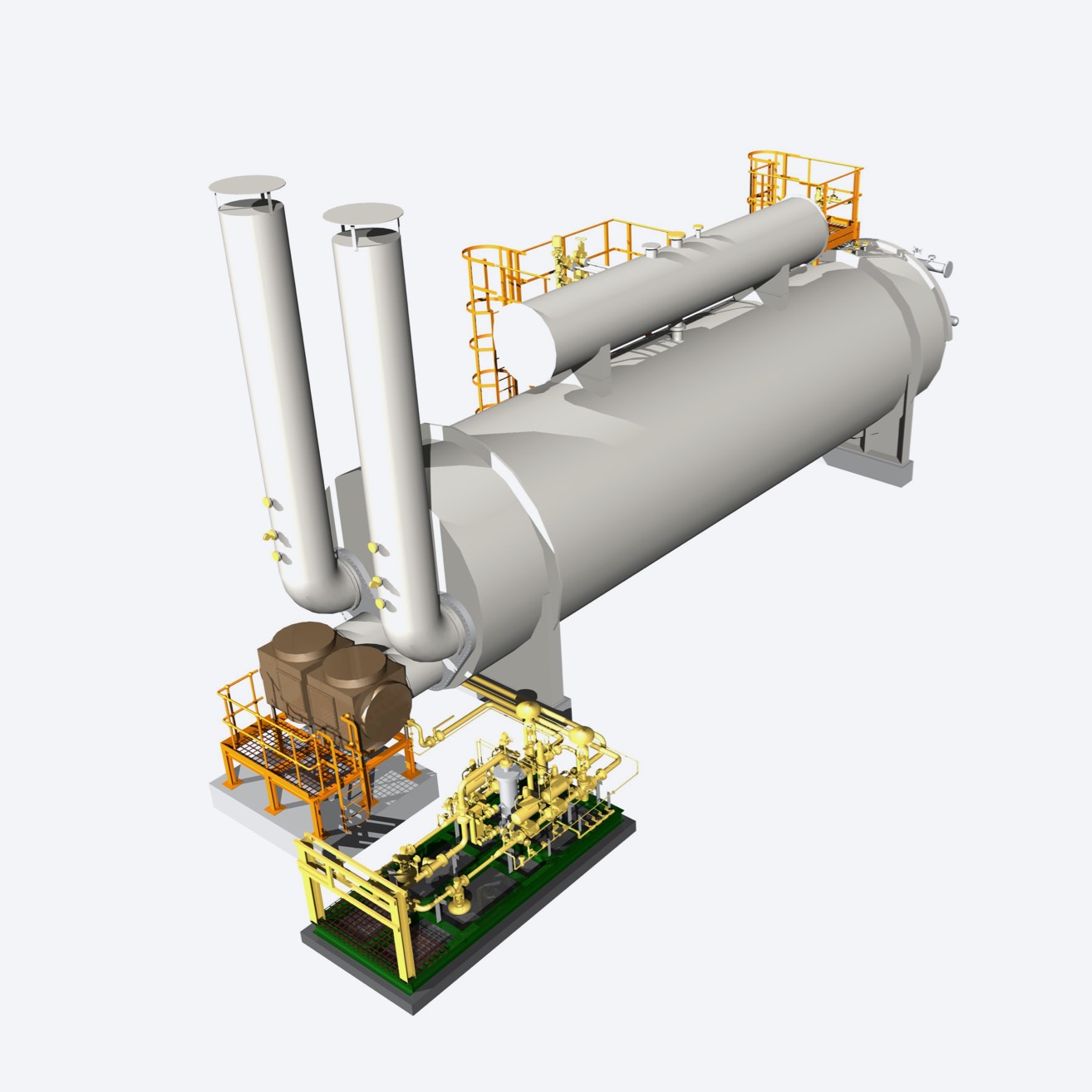

We specialize in design, fabrication, and customization for two and three-phase separators with proprietary internals for service in the upstream and early-production facilities.

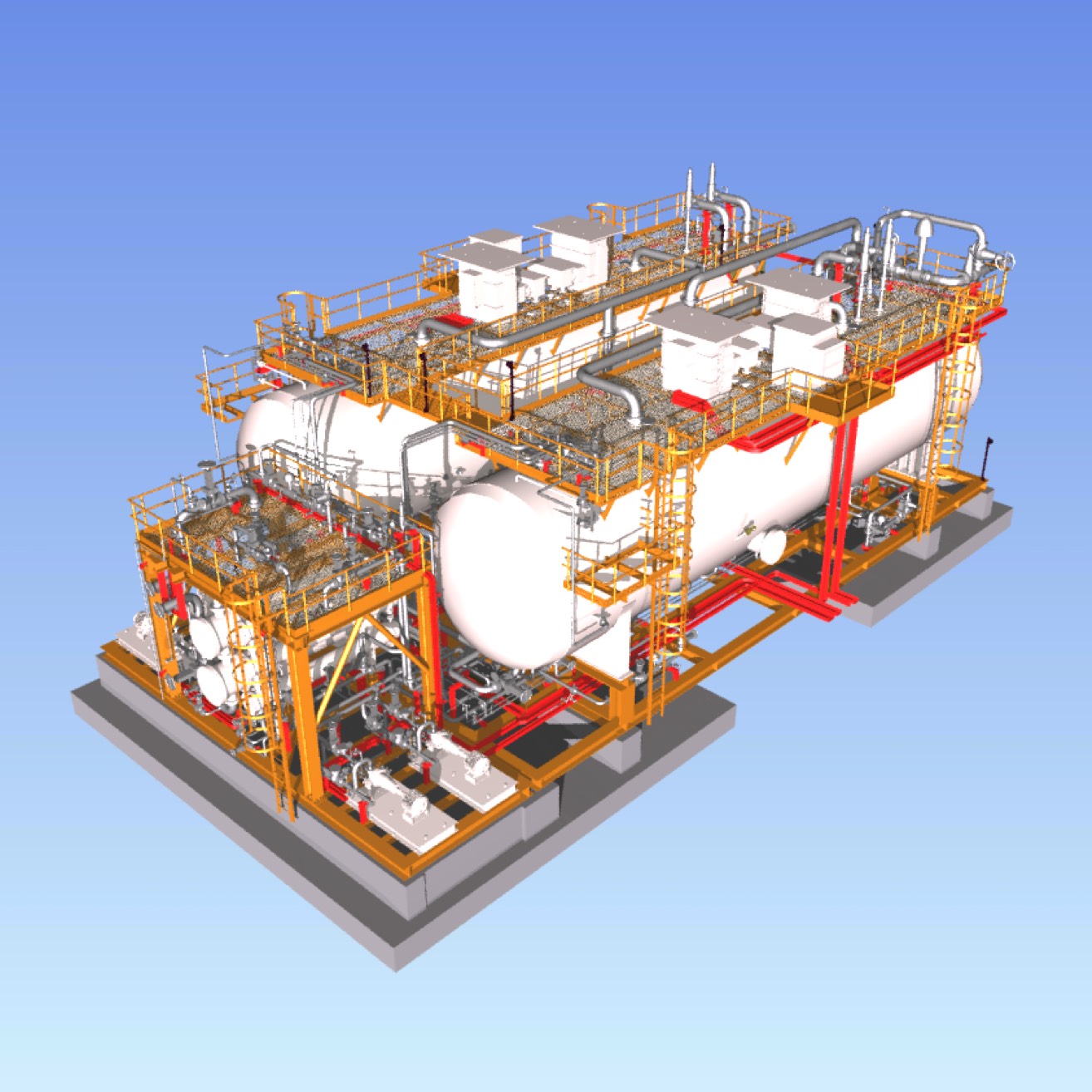

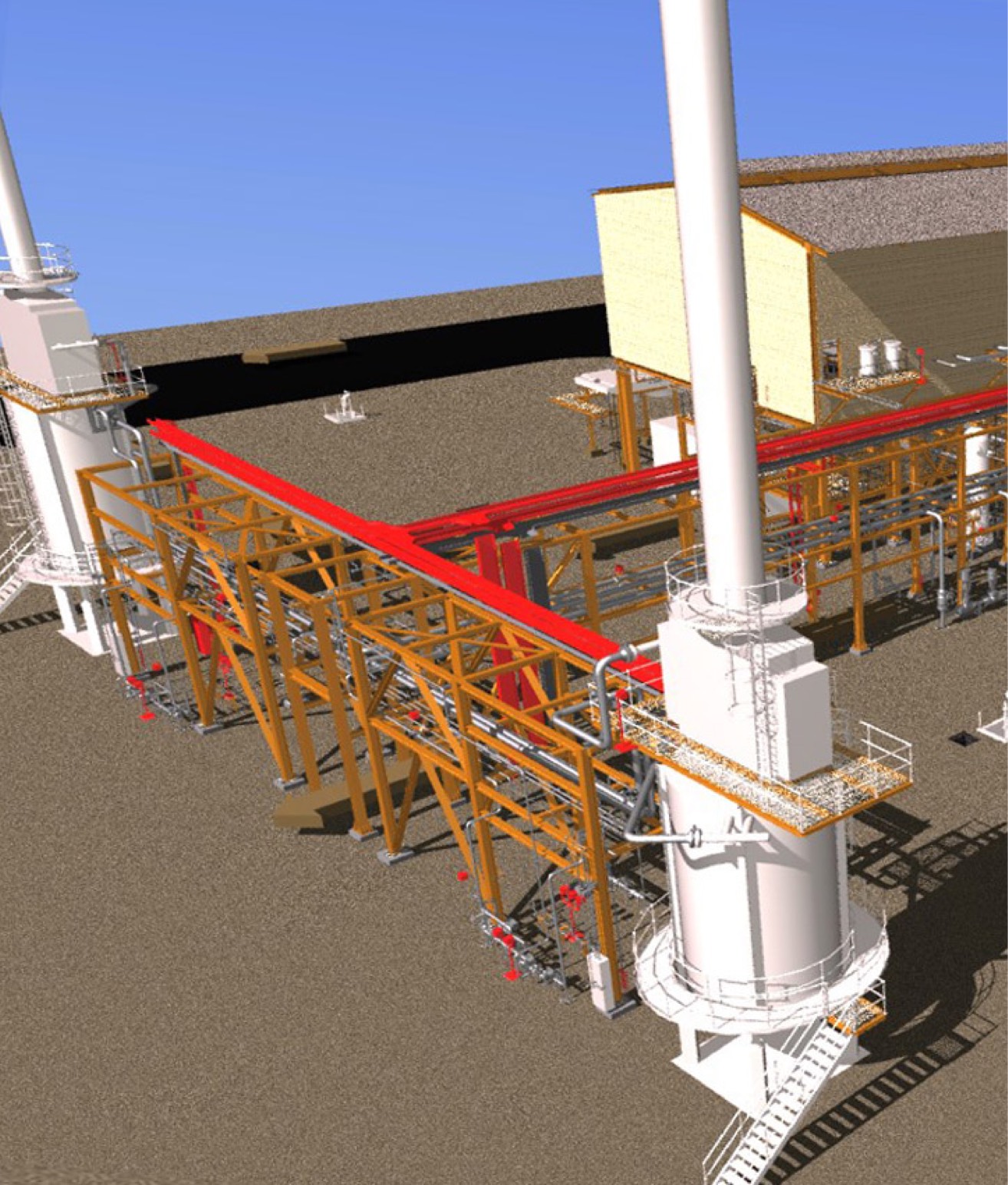

Petro-Techna offers upstream and Early Production Facility solutions for conditioning and stabilizing oil from reservoirs for storage and transport. This is achieved through piggybacking a combination of heating and mechanical separation (gravitational or electrostatically assisted) unit processes.

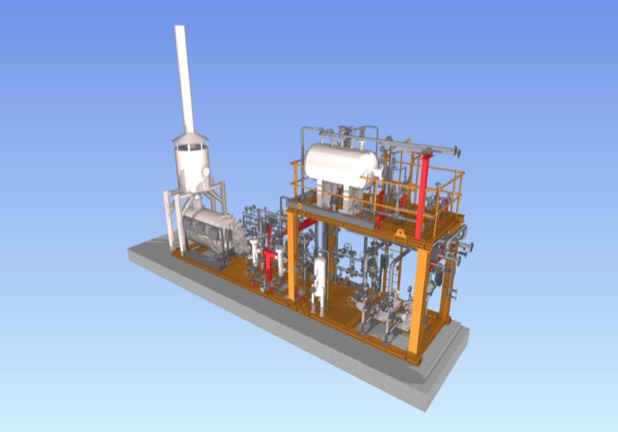

We offer comprehensive produced water treatment solutions to meet the entire range of wastewater treatment requirements. Our solutions are compact, fit-for-purpose, and engineering to meet even the stringent disposal criterion.

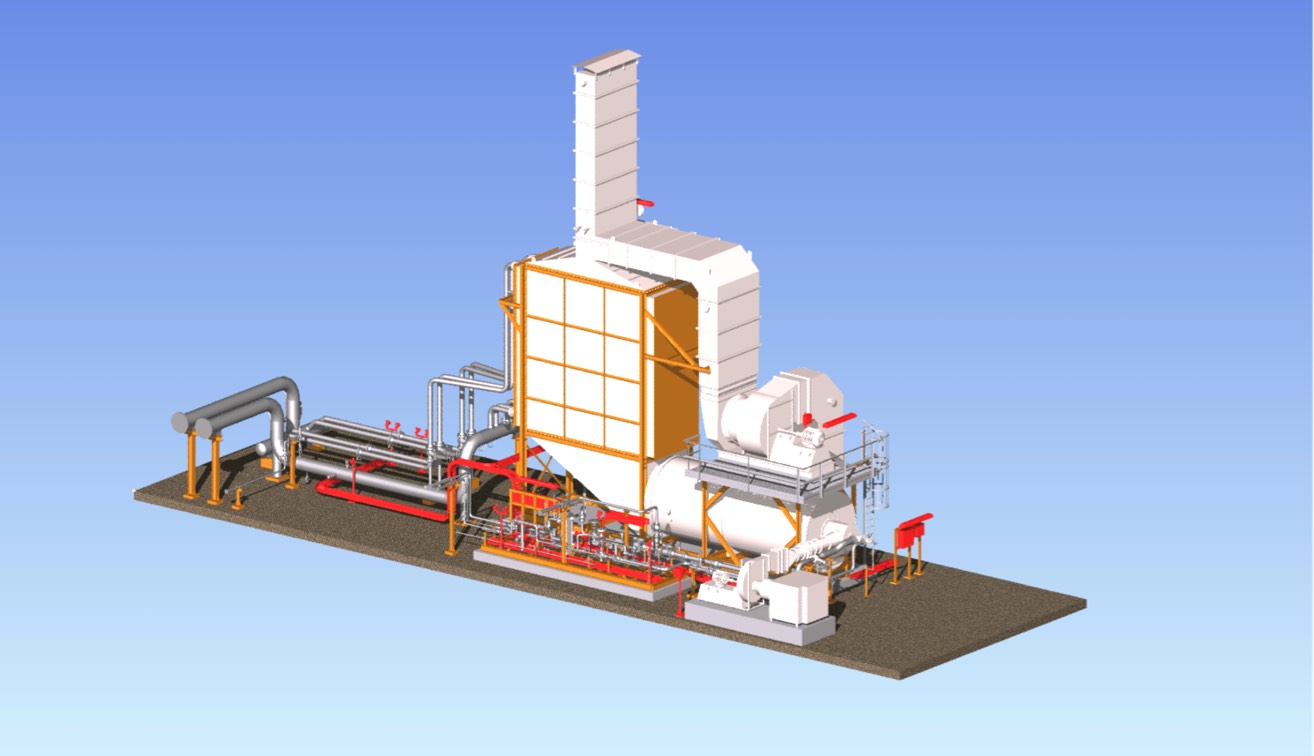

We offer a variety of customized solutions for gas processing, treating and conditioning.

Petro-Techna provides custom design closed loop heat transfer systems utilizing various media including commercial hot oils, water/glycol mixtures and other fluids.