Water Process

Water Process

Produced Water Treatment Solutions

We offer comprehensive produced water treatment solutions to meet the entire range of wastewater treatment requirements. Our solutions are compact, fit-for-purpose, and engineered to meet even the most stringent disposal criterion.

Primary Treatment Options for bulk/free oil and solids separation utilizing

- Conventional gravity-based API separators and settling tanks with specially engineering internals

- Assisted gravity-based CPI separators

- Centrifugal based hydro-cyclone separators

- All these options are equipped for bulk solids removal and concentration

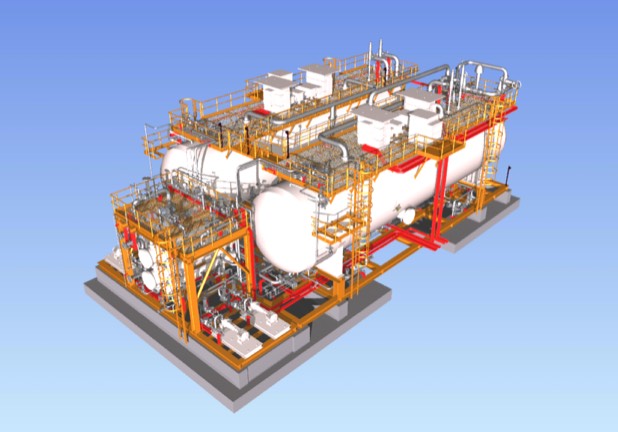

Secondary Treatment Options for high efficiency dispersed oil/fine solids removal utilizing

- Froth floatation technology using Dissolved/Induced Gas Flotation microbubbles process

- Both options can be engineered for any size throughput through single or multiple cells and are available as standalone or fully-equipped skids

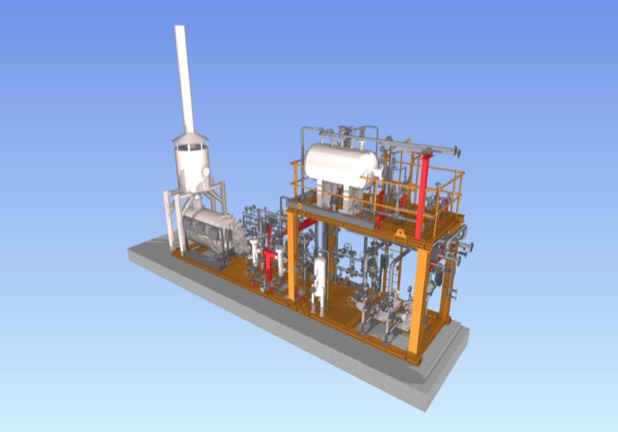

Tertiary Treatment Options for polishing

- Oil Removal Filters with filtering media selection based on feed water characteristics and required outlet water specification

In addition, all our solutions are designed to be emissions proof with inert/fuel gas blanketing with Vapor collection.

View Our Vapor Recovery Process

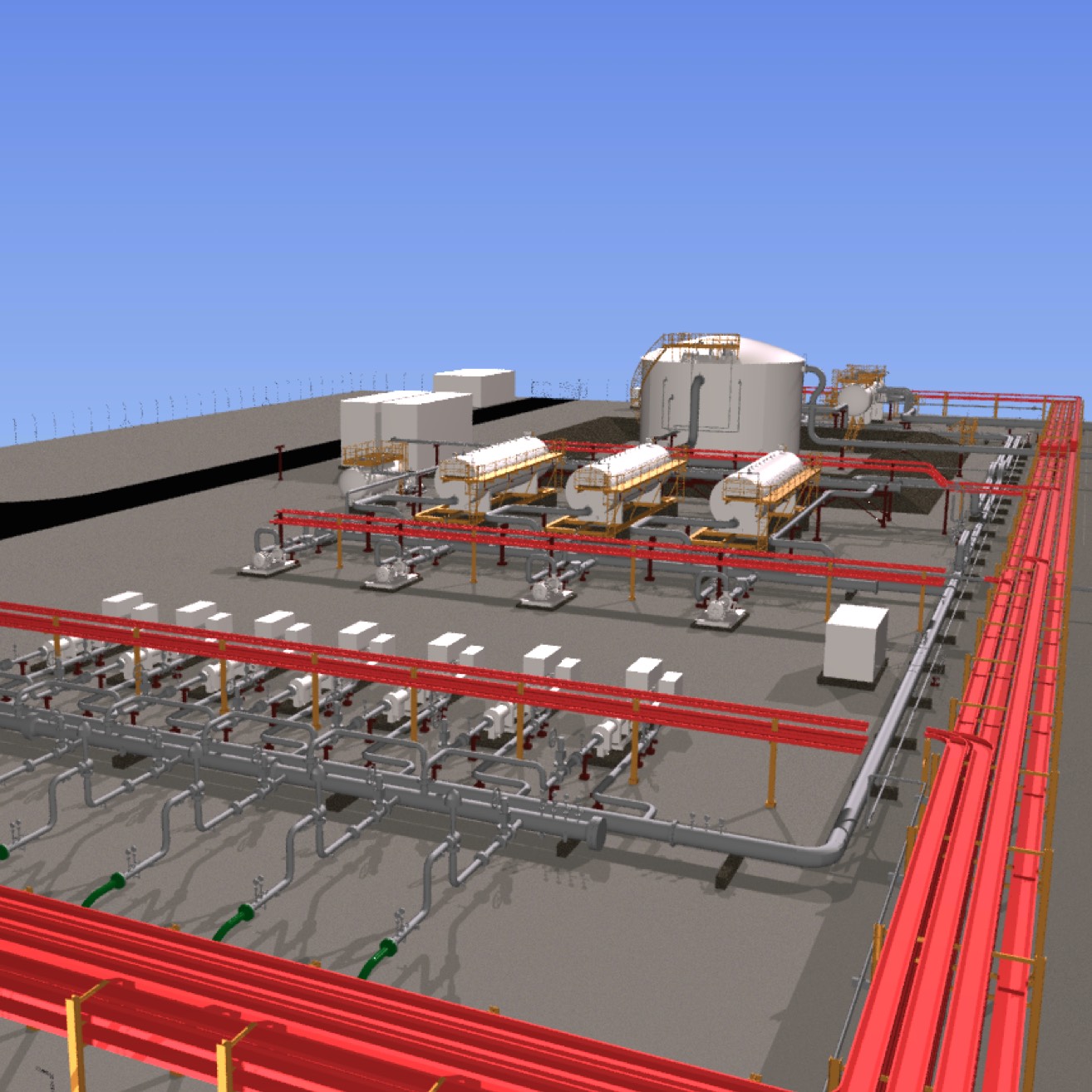

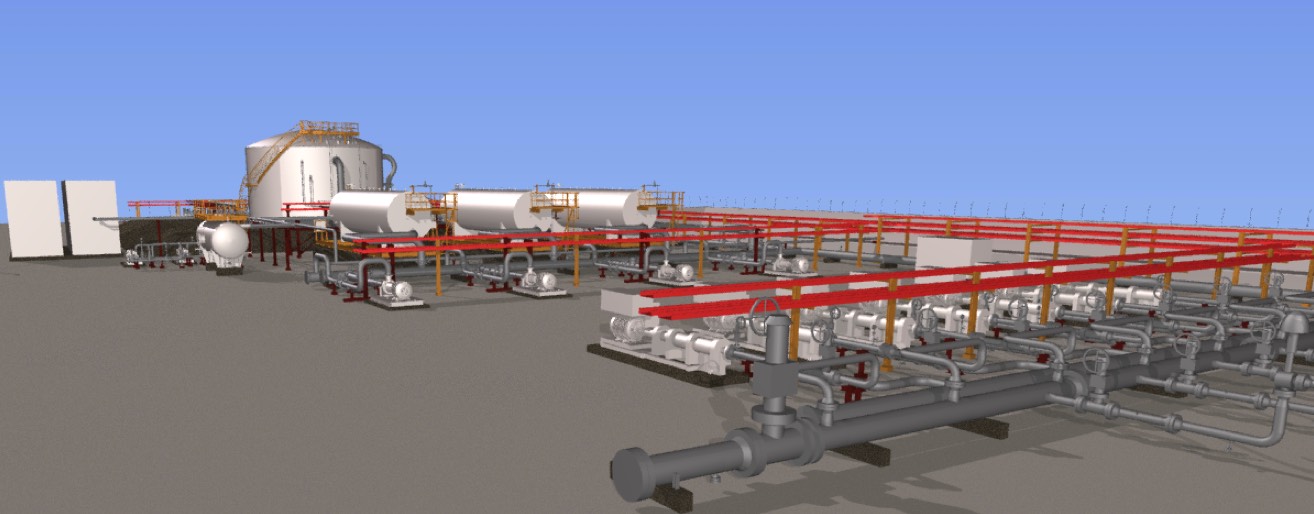

Integrated Produced Water Treatment & Recovery Plants

We are proud to offer our Integrated Produced Water Treatment & Recovery plant as a complete solution for sustainable operations to our clients. Utilizing a combination of all our Produced Water treatment solutions; we offer collection, transport, treatment, and safe disposal of the treated produced water while eliminating sour vapor emissions and recycling the recovered oil. Some of the salient features our plant design includes:

- The ability to operate at low turndown capacity (30% or lower) stably without requiring operator intervention or bulk storage facilities

- Optimized material selection for the plant to achieve economies in installed cost. Presence of H2S in highly mineralized water creates unique challenges which require an all-encompassing holistic approach to make the project economically viable

- An optimized plant layout which minimizes the footprint of the installed facilities and provides excellent accessibility for operations and maintenance

- Custom designed, compact, and weatherproof (sheltered or containerized) utilities including Instrument Air, Nitrogen, and Vapor Recovery to provide self-sustaining operations for units sited far from main processing facilities

- Overall self-regulating operational design using a controls system which enables unmanned operations for extended periods of time

- Offered as:

- Grassroots plants that can be developed as part of new facility design as well as integrated within existing facilities

- Brownfield revamp solutions including solutions for existing pond remediation solutions

In addition, we are making advancements towards reuse of the treated water through targeted research and development as well as solutions for recovered vapor treatment and utilization.

View Our Research & DevelopmentFind Out More

Liquid Process

With over a hundred operational installed units world-wide during the past 3 decades, Petro-Techna represents a premier trusted and well-known brand in the oil desalting field.

Gas Process

We offer a variety of customized solutions for gas processing, treating and conditioning.

Utilities / Auxiliaries

Petro-Techna provides custom design closed loop heat transfer systems utilizing various media including commercial hot oils, water/glycol mixtures and other fluids.